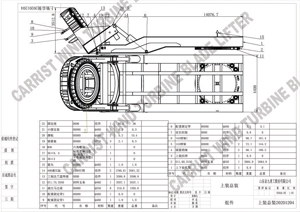

wind turbine blade lifter transport

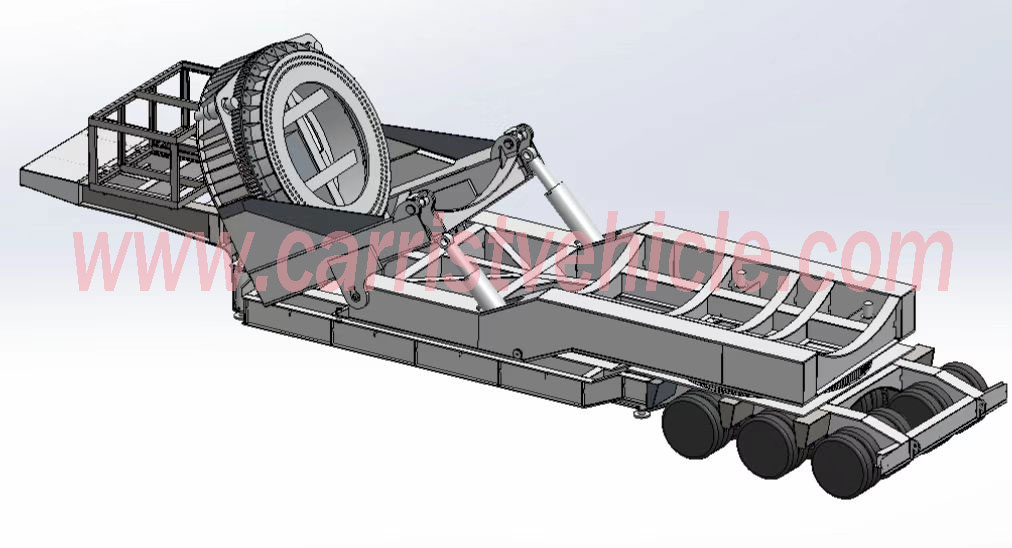

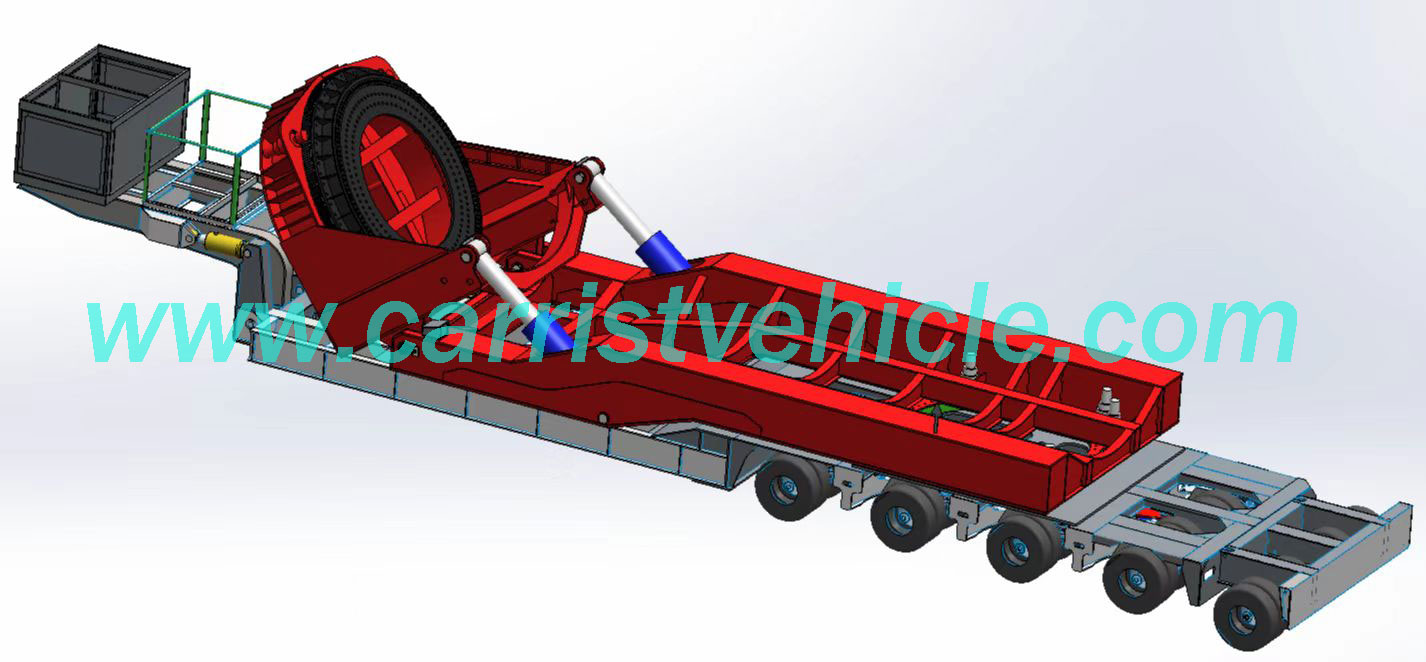

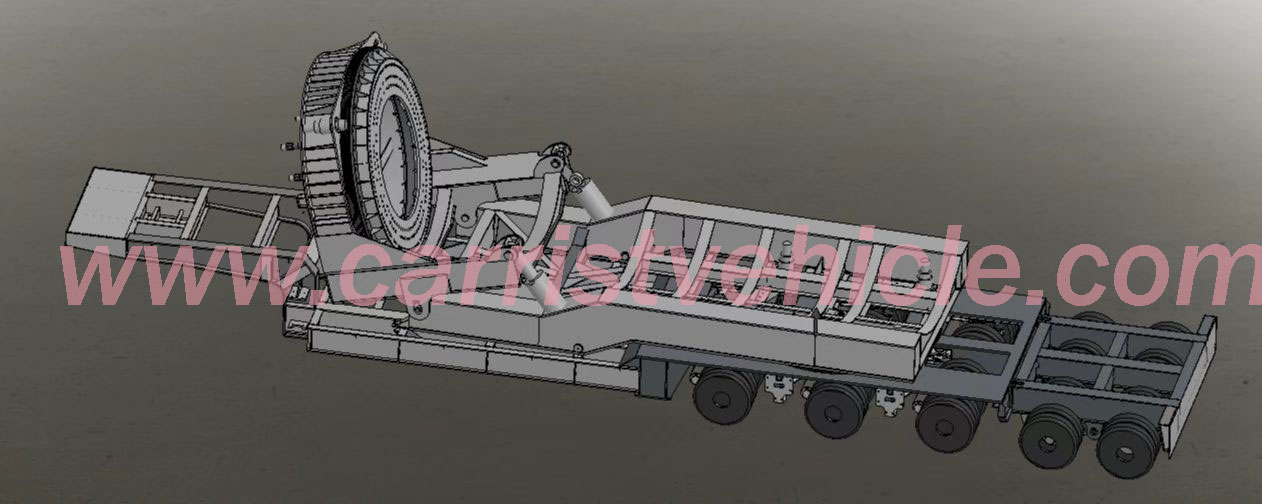

Carrist wind turbine blade lifter transport vehicle

is a specialized device or equipment that is used to lift and install wind turbine blades onto the wind turbine hub. These blades typically weigh several tons each and can be up to 120 meters long. The blade lifter makes it possible to safely and efficiently install wind turbine blades, which is a crucial part of the process of building a wind farm.

The lifter is typically mounted on a large vehicle or mobile crane system, and it operates using a hydraulic system. The device includes a set of jaws or clamps that can securely grip onto the wind turbine blade, and then lift it into position to be mounted onto the turbine hub.

The blade lifter is designed to be highly durable and reliable, as it must withstand harsh environmental conditions and often needs to be used in remote locations with limited access to support services. It is an essential piece of equipment for the construction and maintenance of wind turbines, which are becoming increasingly important as a source of renewable energy.

The specifications of a wind turbine blade lifter can vary depending on several factors, such as the size and weight of the wind turbine blades to be lifted and installed, the height of the wind turbine tower, and the specific requirements of the construction project. However, here are some common specifications that are typical for many wind turbine blade lifter systems:

· Lifting capacity: The lifter must be able to handle the weight of the wind turbine blade(s), which can range from a few tons to up to 20 tons or more per blade.

· Lifting height: The lifter must be able to lift the wind turbine blades to the required height for installation onto the turbine hub, which can be several hundred feet in the air.

· Hydraulic system: The lifter operates using a hydraulic system that must be capable of generating enough force to lift the wind turbine blades.

· Control system: The lifter is typically controlled remotely using a set of manual or automatic controls, which must be highly responsive to ensure accurate positioning and control of the blades during installation.

· Mobility: The blade lifter must be mounted on a vehicle or mobile crane system that can move around the wind farm site and access the different turbine tower locations.

· Safety features: The lifter must include multiple safety features, such as overload protection, emergency stop buttons, and safety interlocks to prevent uncontrolled movements or potential hazards.

· Durability: The lifter must be able to withstand harsh environmental conditions, including strong winds, heavy rain or snow, and extreme temperatures, as well as being corrosion-resistant to withstand the effects of saltwater in coastal locations.

Overall, wind turbine blade lifters are highly specialized pieces of equipment that require careful design and construction to ensure safe and efficient installation of wind turbine blades.