Big Ceiling Fans

Large air coverage: These fans are designed to move large volumes of air and cover a wide area, providing efficient and effective cooling and ventilation for industrial spaces.

Energy efficient: CARRIST HVLS Fans are engineered to deliver high airflow with low energy consumption, resulting in significant energy savings compared to traditional industrial fans or HVAC systems.

Quiet operation: These fans are designed to operate quietly, creating a comfortable working environment without excessive noise disruption.

Enhanced air circulation: CARRIST HVLS Fans promote better air movement and circulation in large spaces, helping to reduce stagnant air, humidity, and condensation. This can have a positive impact on indoor air quality and overall comfort levels.

Improved worker comfort: The large, gentle breeze created by these fans helps to reduce perceived temperatures and improve thermal comfort for workers, increasing productivity and overall satisfaction.

Durable construction: CARRIST HVLS Fans are built with high-quality materials and robust construction, ensuring long-term reliability and minimal maintenance requirements.

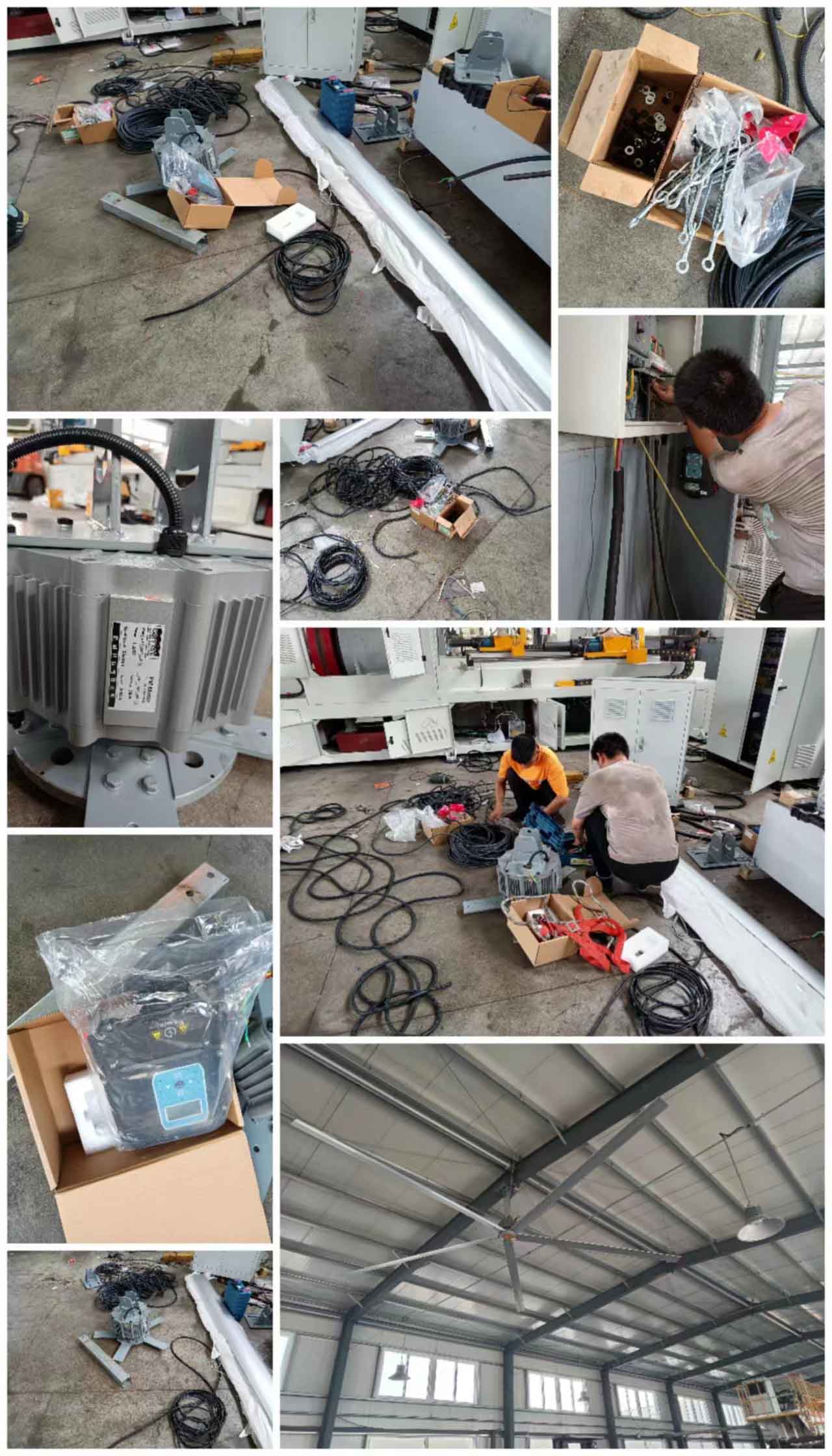

Versatile installation options: These fans can be installed in a variety of industrial settings, including warehouses, manufacturing facilities, gyms, and more. They can be mounted on ceilings or walls, offering flexibility in placement and maximizing space utilization.

Smart control options: CARRIST HVLS Fans often come with smart control features, allowing easy operation and adjustment of fan speeds, timers, and remote control capabilities.

Carrist HVLS Fan (PMSM) Product Data Sheet | |||

Model | 凯歌 KG-7300 | Diameter | 7300mm |

Blade No. | 5 pcs | Weight | 110KG |

Power | 1.2kw | Rated Current | 6A-3A |

Noise value | <39dB | Coverage | 1000M2 |

Max Wind Speed | 3.5m/s | Average Wind Speed | 约 2m/s |

Air Volume | 14800m³/min | Speed | 55RPM |

Drive Device | l The permanent magnet inner rotor motor adopts vacuum epoxy encapsulation, achieving IP65 protection level, dust resistance, and oxidation resistance. l The thermal conductivity coefficient is 1.0 W/(m * k), and the permanent magnet can withstand high temperature of 180 °. l The designed service life of the motor is 15 years, 100% maintenance free. l Transmission structure: The inner rotor structure is connected to an independent chassis to bear the rotation of blades, with good dynamic balance and stable and reliable structure. l Equipped with servo function and strong electromagnetic calculation ability, the motor control adopts digital vectorization control to accurately control the motor. | ||