Arc welding robot

Carrist Robot-based automation increases the efficiency of welding processes and enables your organization to manufacture more parts in less time, while minimizing scrap, increasing quality and improving the working …

Carrist welding device of spot welding robotic adopts blanketed welding tongs, and the welding transformer is mounted at the back of the welding tongs, so the transformer must be as small as viable. for transformers with small capacity, 50hz power frequency ac may be used, even as for transformers with huge capability, inverter technology has been used to trade 50hz strength frequency ac into 600-700hz ac, reducing and lowering the quantity of the transformer. after voltage transformation, 600~700hz ac energy may be right away used for welding, or secondary rectification may be completed for welding with dc strength. the welding parameters are adjusted via the timer. the contemporary timer has been computerized, so the robot control cabinet can straight away manipulate the timer without extra interface. the welding tongs of spot welding robotic typically use pneumatic welding tongs. the outlet most of the 2 electrodes of the pneumatic welding tongs is normally most effective two stages of stroke. furthermore, once the electrode strain is about, it can't be modified at will. carrist new type of electric powered servo spot welding tongs has seemed. the hole and last of the welding tongs are pushed by the servo motor and fed back by using the code plate, in order that the hole degree of the welding tongs may be arbitrarily selected and preset consistent with the actual goals.

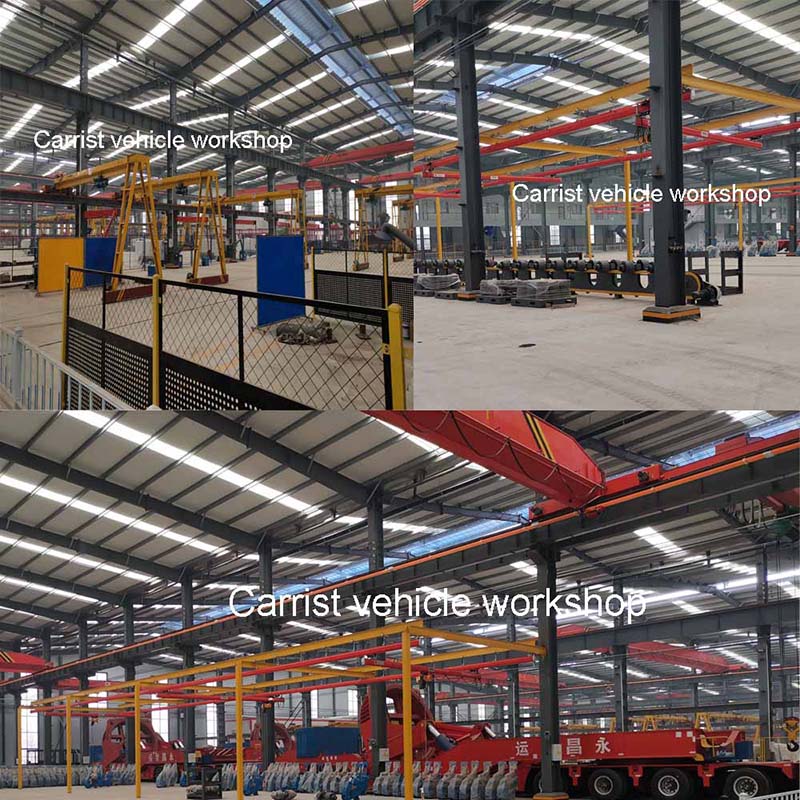

Workshop of Arc welding robot